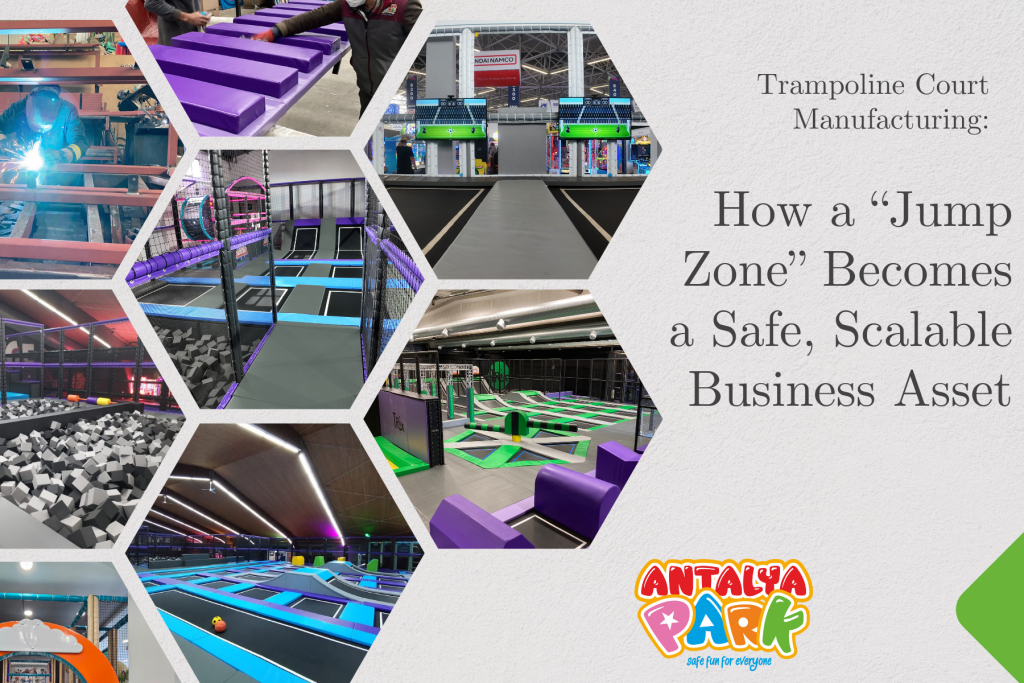

Trampoline court manufacturing is not just about producing jump beds. It’s about engineering a complete, high-load system that controls energy, protects users, and stays reliable under heavy daily traffic. A trampoline court may look simple—rectangular beds, padding, and a few surrounding features—but the quality of manufacturing determines safety performance, operating stability, and long-term profitability.

This article explains what trampoline court manufacturing includes, what matters most in production, and how to evaluate quality like an operator (not just a buyer).

1) What Is a Trampoline Court?

A trampoline court is typically a structured jumping area made up of multiple connected beds, often installed inside:

- trampoline parks

- soft play and FEC venues

- sports and activity centers

- school or recreation facilities

Compared to a full “park concept,” a court focuses on the jumping zone itself—yet it still demands professional engineering and disciplined manufacturing.

2) What Trampoline Court Manufacturing Includes

A complete trampoline court is built from interconnected systems, including:

- Steel frame structure (load-bearing foundation)

- Jumping beds + tensioning system (springs or alternative tension systems)

- Edge and corner padding (impact protection and safe borders)

- Netting/barriers (separation where required)

- Platforms and transitions (safe movement between zones)

- Fixing and connection points designed for long-term stability

- Documentation for installation, inspections, and maintenance routines

Good manufacturing is about consistency and precision—because small weaknesses multiply under constant dynamic load.

3) Safety Engineering: The Non-Negotiable Core

A trampoline court is “physics in public.” Every jump creates dynamic force that travels through the frame, the tension system, and the borders. Strong trampoline court manufacturing focuses on:

- stable structural design and secure anchoring

- consistent bounce behavior through correct tension distribution

- impact-safe perimeter design (padding quality, edge coverage, safe gaps)

- controlled transitions that reduce missteps and collisions

- durable, non-toxic materials for public environments

- fire-resistant material options for commercial venues

- planning aligned with recognized safety approaches (EN / ASTM)

Safety isn’t a label—it’s how the court behaves after months of heavy use.

4) Durability: Where Profit Is Protected

The biggest hidden cost in trampoline operations is downtime. That’s why durability is not “nice to have”—it’s revenue protection.

High-quality trampoline court manufacturing pays attention to:

- frame stability and resistance to loosening over time

- bed and stitching quality (fatigue resistance)

- tension system performance consistency

- pad cover wear resistance (tearing + cleaning durability)

- net fixing strength and long-term tension stability

- corrosion resistance in metal components

A durable court stays tight, clean, and safe longer—reducing closures and customer complaints.

5) Installation Quality and Maintenance Readiness

A trampoline court is built twice: in the factory and on site. Manufacturing must support installation discipline through:

- clear technical drawings and labeling

- organized packaging and step-by-step installation logic

- inspection-friendly access points for daily checks

- documented maintenance routines (daily/weekly/monthly)

A well-manufactured system makes operation easier—not harder.

Conclusion

Trampoline court manufacturing is the process of turning a high-energy idea into a safe, durable, and operationally stable attraction. When engineering, materials, precision production, and support are done correctly, a trampoline court becomes more than a jump zone—it becomes a scalable business asset that drives repeat visits and performs reliably year after year.